The ultra intelligent wind solar complementary controller is a new generation of new energy application control equipment designed by our company based on ultra-high performance controllers, especially for wind turbine power generation, and has made qualitative changes in typhoon protection and safety. Make the wind turbine operate reliably and safely (such as continuous power generation with limited speed and current). The controller is developed based on years of application experience, such as waterproofing, dust prevention, salt spray, incorrect operation wiring, wind turbine wind resistance limit control, etc. It adopts a layered and modular structure, which is easy to quickly customize and suitable for applications.

Performance characteristics

1- Industrial grade appearance design, beautiful and elegant, rich in texture, all materials are selected from industrial grade, and the working temperature can reach -40 ℃ -85 ℃.

2– Visual 3-digit high brightness digital display interface, easy to operate and recognize.

3- Reliable waterproof performance (circuit board three proof treatment, layered structure design), even if water enters (in small amounts), it will not damage the equipment.

4- Standard RS232 communication, easy to cooperate with computer software for monitoring. (RS485, short distance wireless optional), using USB to RS232 components, more convenient for data exchange with computers (computers with USB interfaces can be used), no need to use battery power when configuring parameters.

5- Injection molding technology is used at the terminal block to prevent short circuits and wire collisions, ensuring safer operation for customers.

6- The continuous reverse connection of the battery input terminal will not damage it, and there will be a buzzing alarm. Avoiding equipment damage and fire caused by wiring errors, and better protecting the battery.

7- The input end of the photovoltaic panel will not be damaged if it is continuously reversed, and there will be a buzzing alarm prompt. Especially during nighttime construction, it will not cause wiring errors.

9- Provide MPPT function (boost/fan, buck/photovoltaic), allowing the fan to charge the battery even at low wind speeds and improve wind energy utilization. (Optional accessories).

10- The patented wind turbine stable speed control method can prevent the wind turbine from running at excessive speed. The advantage is that during strong winds, the wind turbine can still maintain stable speed for power generation, greatly increasing the wind turbine’s power generation. I won’t brake directly and stop the fan operation when speeding as usual.

11- Patent type fan stall current limiting control method, which can prevent the fan from operating under overcurrent and protect the expensive generator from being damaged by overheating caused by overcurrent.

12- Open parameter setting modes such as overcharging and discharging of batteries can make the controller suitable for various types of batteries (such as lead-acid batteries, lithium batteries, etc.).

13- Ultra low static standby current, ensuring minimal self power consumption and avoiding significant battery energy loss, especially in long-term continuous rainy weather, the battery will not be depleted.

14- The use of lightning protection components can effectively prevent damage caused by induced lightning strikes, further improving equipment reliability.

15- Using an open software platform (computer software), customers can quickly and easily customize their own applications (through software or controller panels), and support centralized monitoring function. Through the 485 bus, all devices can be connected. The communication distance reaches 2KM.

16– In addition to displaying the current, voltage, and power of conventional fans, photovoltaics, batteries, and output terminals, the controller screen also displays the cumulative power generation of fans and photovoltaics, as well as the remaining battery capacity, fan speed, and unloading current. Temperature display of the controller.

17- Original controller terminal facing up alarm function. When the controller terminal is facing up, there is an alarm prompt, allowing customers to use it in the correct installation direction, avoiding outdoor use or weather conditions where the surface of the wire condenses and rainwater directly flows into the interior of the controller, leading to the possibility of damaging the controller after a large amount of water accumulation.

18- The controller integrates temperature monitoring function internally, constantly monitoring the temperature of the equipment, making the controller work safer and extending the service life of the equipment.

Parameter Table of Super Intelligent Wind Solar Complementary Controller

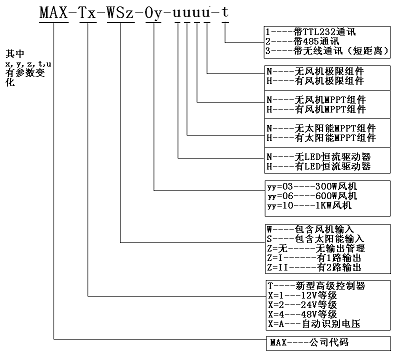

| 型号 | MAX-Tx-WSz-0y-uuuu-t | ||

| 电池参数 | |||

| 额定电池电压 | 12V / 24V 自适应 48V人工设置 | ||

| 电池保护方法 | 反接保护(不烧任何部件,有语音提示);过压保护,欠压保护(对于路灯类负载) | ||

| 电池温度补偿 | 5mv/℃/2V (可设)(选配件) | ||

| 风机输入参数 | |||

| 额定风机功率 | 250W/12V等级 400W/24V等级 | ||

| 风机输入额定电流 | 18A dc(整流后直流;对应风机交流输入约15Aac) | ||

| 风机至大输入电流 | 25A dc(整流后;对应风机交流输入约20Aac) (工作时间<=0.5小时) | ||

| 风机至大转速限制 | 500 Rpm (可设) | ||

| 风机输入至大电流限制 | 15A (可设定) | ||

| 风机保护方法 | 空载输入保护,超压保护(语音提醒),过转速保护,过流保护,感应雷击保护 | ||

| 卸荷方式 | PWM无级高频软卸荷(无外接电阻),或外接电阻均可。 | ||

| 风机MPPT功能 升压型MPPT(选配) | 适合电池电压等级 | 12V /24V | |

| 至大输入限制电流 | 5A | ||

| MPPT启动输入电压点(参数) | 12V (出厂值) 参数可设 | ||

| MPPT关闭输入电压点(参数) | 6V (出厂值) 参数可设 | ||

| MPPT通道限定电流(参数) | 1.5A(出厂值) 参数可设 | ||

| 工作转换效率 | >90% | ||

| 工作模式 | PWM动态变阻匹配跟踪方式 | ||

| 光伏输入参数 | |||

| 光伏额定输入电流 | 15A | ||

| 光伏额定输入压降 | <=0.15V | ||

| 光伏保护方法 | 反接保护(语音提醒),过流保护,感应雷击保护 | ||

| 卸荷方式 | 开路卸荷 | ||

| 光伏MPPT功能 降压型MPPT功能(选配) | 适合电池电压等级 | 12V /24V | |

| 至大输入电压 | 55V | ||

| 至大输入电流 | 10A | ||

| 工作转换效率 | >90% | ||

| MPPT效率 | >99%(自动跟踪***大功率点) | ||

| 放电输出口参数 | |||

| 输出路数 | 2路输出,(独立控制) | ||

| 额定输出电流 | 14A(每路) | ||

| 过流保护限制电流 | 15A(持续25秒保护) 18A(持续4秒保护) | ||

| 保护方式 | 过流保护(保护后,语音提醒,异常可恢复) | ||

| 输出模式 | 光控,时控,晨亮,保持输出 | ||

| 其他 | |||

| 辅助功能 | 温度显示(过温报警),控制器倒置显示(端子端朝上,语音提醒) | ||

| 显示方式 | 液晶显示(专用)或软件显示 | ||

| 通讯方式 | TTL232 RS485/USB接口/短距离无线(选配) | ||

| 显示内容(供参考,具体参数根据实际设备有变化) | 风机输入电压,电流,功率,发电量,转速,卸荷电流,和异常信息 光伏输入电压,电流,功率,发电量,和异常信息 电池电压,充电电流,功率,总充电量,电池状态信息 2路常规输出端口输出电流,功率,和异常信息 | ||

| 待机耗电量 (屏幕背光关) | 约20ma /12V系统 约18ma /24V系统 实际依据配件不同相应增减。所有配件安装时总电流<30ma | ||

| 操作方式 | 3M贴膜按键操作(4按键) | ||

| 工作温湿度范围(环境) | -40~+65℃/20~85%RH(但无结露) | ||

| 防护等级 | IP41 | ||

| 控制器尺寸(长*宽*高*) | 115mm*148mm *84mm(常规型号) | ||

| 重量 | 1KG(常规型号) | ||

| 为了更好的服务于客户,我公司可根据客户要求调整和配置参数。 | |||